Welcome to the wonderful world of crown molding. Your adventure starts here.

When it comes to trim, crown is king.

Crown molding adds an immediate pop of interest to a room for not much cost.

But here’s the sad truth: walls and ceilings are rarely square, and corners are rarely a perfect 90 degrees.

It can be a bit overwhelming at first. All those angles, flipping the crown upside down against the fence (or was it right side up?), changing the miter (or was it the bevel?). Inside corners…outside corners…after a while it all starts to blur together.

It's okay -- you CAN do this.

Whereas I used to take repeated trips back and forth to the miter saw cursing under my breath, now I can take one look at a difficult corner and say, “My name is Inigo Montoya. You killed my father. Prepare to die.”

Here are the 6 essential tools you’ll need to measure, cut, and install crown molding. I promise if you follow my tips you won’t need to use half a tube of caulk to cover up your mistakes 😄 Not that I’d know anything about that…moving on…

Essential Crown Molding Tool #1: A Measuring Tape

Grab a buddy and measure the walls in your room. If you have one of those fancy laser measurement tools, even better. Map out your dimensions on a piece of graphing paper. I like to draw a mockup of the room and label all the corners in advance. Jot the measurements down, then add 10-15% excess. If you’re new to crown molding, maybe add a bit more.

Now here’s something no one tells you about crown molding. When you’re measuring for your cuts, you’ll want to measure where your crown hits the wall, not the ceiling. You’re measuring the bottom "or run" of your crown, so to speak.

Lastly, if you have a really long piece of crown, add 1/8” to your measurement so that you have a little wiggle room. You can always trim a bit off, but it’s nearly impossible to hide your mistake on a piece that’s even 1/8" too short.

This post contains affiliate links. For more, see my disclosures.

Essential Crown Molding Tool #2: A Protractor

Invest $30 in a protractor and save yourself some heartache. It doesn't have to be digital, but it should be at least 16" long. Why? Because corner caps applied by builders add thickness to drywall and can skew your reading. If your protractor extends past the first wall stud, you'll get a more accurate measurement of the angle in question.

That being said, I've only ever used a 7" protractor like this and I've never had an issue with it. But now I've covered my bases so the professionals won't come at me for recommending something sub par.

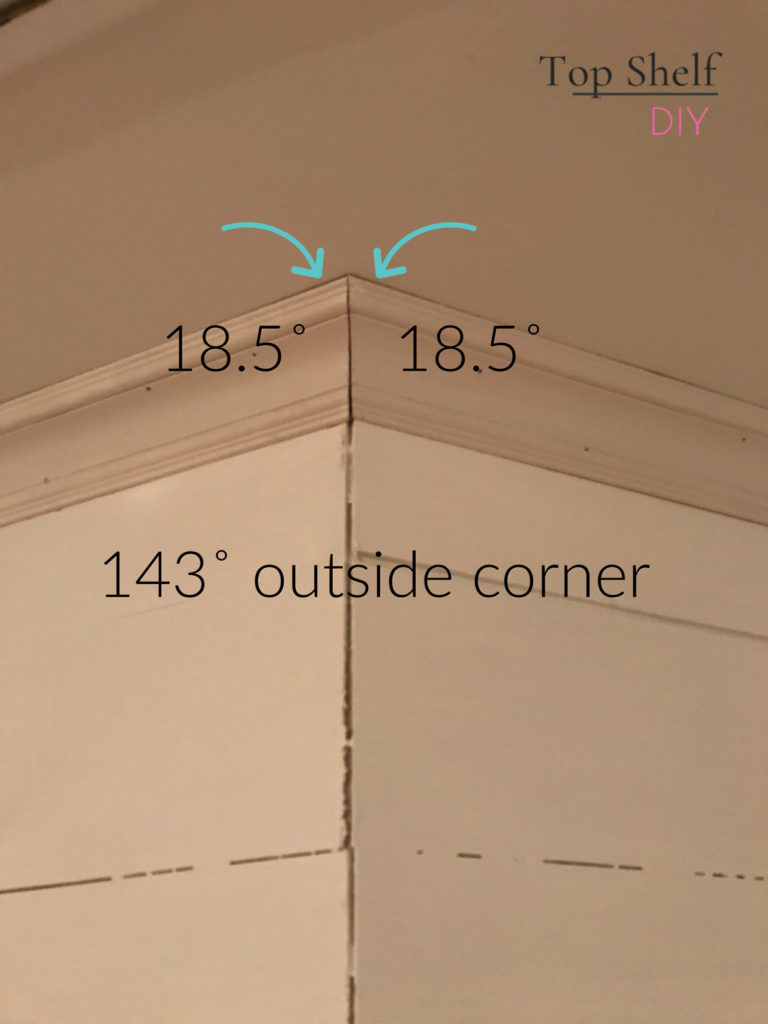

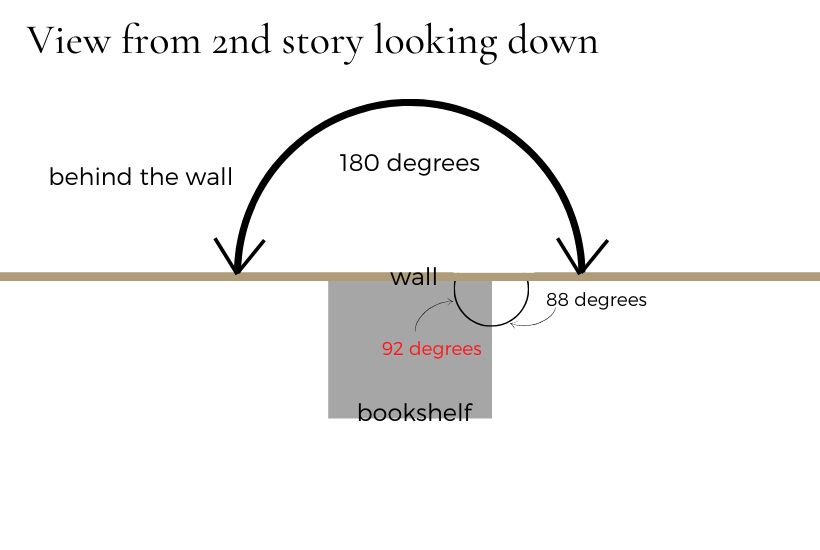

Think of the space behind your wall as 180 degrees, and the space in front of your wall as the other 180 degrees. After measuring your corner angle, subtract it from 180 degrees. Divide this number by 2, and you have your magic number.

Your magic number = the two cuts needed to form your mitered joint.

Quick Protractor Example

Let’s say your inside corner is 88 degrees instead of 90 degrees (which happens a lot). Your inclination is to cut two pieces at 44 degrees, right? Wrong.

180 – 88 = 92

92/2 = 46 degrees.

That’s a two-degree difference from your original guess. That’s the difference between a gap and no gap in your finished product.

Essential Crown Molding Tool #3: A Miter Saw

Well naturally you can’t make any of these cuts without your handy dandy miter saw! I wasn’t so sure about using a power saw in my early DIY days, but I learned the ropes and never looked back. My miter saw is hands-down my favorite power tool in my garage (with the table saw being a close second).

It didn’t take me long to realize that my 7 ¼” miter saw wasn’t going to take me very far in the crown molding department. Not only was the fence too small, but I couldn’t raise my blade high enough to cut through the molding! Eventually I upgraded to a sliding 12-inch miter saw and reserved the smaller saw for chair rails, wainscoting, etc.

Moral of the story, get yourself a nice beefy miter saw if you’re planning to tackle crown molding someday. I’ve also heard it’s a good idea to swap out the factory blade sooner rather than later to avoid tear out.

To see how I use the miter saw to make my cuts, check out my video tutorial below:

Essential Crown Molding Tool #4: A Coping Saw

I highly recommend using a coping saw for your inside corners*. It basically entails having one piece of crown run straight to the wall (no mitered cuts) and the other piece cut at a mitered inside cut (at the angle you determined with your protractor).

For your mitered cut, you’ll basically “cope” or cut away everything except the profile so that your crown is resting on top of the piece flush with the wall.

This is what a coped joint looks like as your two cuts are coming together.

For a nice tight fit between your pieces, make sure to cope well. Hold your coping saw at an angle behind your edge so that you’re cutting away as much MDF as possible. Clean it up with a file or sanding wedge if there are any ridges left behind.

Here's the coping saw in action:

*The alternative to the coping method is to cut both inside pieces of crown at 45 degrees (for a 90-degree corner).

You’ll get a much tighter fit with the coping method since your pieces are literally resting on top of each other. Also, homes tend to settle, which can exaggerate any existing gaps in your corner by just cutting two pieces at 45 degrees.

Essential Crown Molding Tool #5: A Nail Gun

Get yourself a nice nail gun – preferably one that doesn’t require a compressor – like the 18-gauge cordless Ryobi that everyone and their grandma uses. It's super easy to load and use. Go with 2-inch brad nails for crown, and try to mark your studs in advance so you can nail right into those. I like to put a small bead of Liquid Nails on the back of my crown right before nailing it to the wall. Just be careful not to use too much or it will seep out and make a mess.

Essential Crown Molding Tool #6: A Caulking Gun

Patch, caulk, and caulk some more!

Hopefully, if you’ve followed all the steps listed above, you won’t need to use a lot of caulk. But let it be a comfort to know that caulk can do wonders for a botched corner...to a certain extent.

The first time I installed crown there was a corner in my living room filled with huge gobs of caulk. It stayed that way until I eventually had the guts to pull it all down and redo it a year later. I’m glad I did.

As a note of caution, caulk isn’t sandable once it dries. Spackling paste is. Choose accordingly. When applying caulk, wet your finger so that it spreads evenly across your surface. It’s better to apply a few thin layers of caulk rather than one large smear of gobbeldy gook since caulk shrinks between applications.

Related: Coped Crown: 5 Mistakes You Might Be Making

...

I hope these tips have demystified the crown molding installation process. Don’t be too hard on yourself if you make some mistakes in the beginning. If nothing else, it’s a great time to learn the ins and outs of your miter saw.

I would be remiss to leave out two of my favorite resources for crown molding installation. See Jane Drill on YouTube has several great videos about making mitered cuts. She is so relatable and keeps her explanations simple. I also love the in-depth visuals provided by Ken over at The Joy of Mouldings.

Once you get past crown molding you’ll be amazed how easily other projects fall into place – cornices, wainscoting, and shiplap, just to name a few!

Cheers,

Erin

Have wasted so much time and material on trying to cut crown molding for an obtuse inside corner. Please help

I explain it further in this video: https://studio.youtube.com/video/B3XYtI-sqEk/analytics/tab-overview/period-default

I'm also working on more installment tutorials, check back here soon!

Video doesn't work

Sorry about that -- it should work now!

i just tried video too and it didnt work! 🙁

Hi David,

Sorry about that. Try this: https://www.youtube.com/watch?v=B3XYtI-sqEk